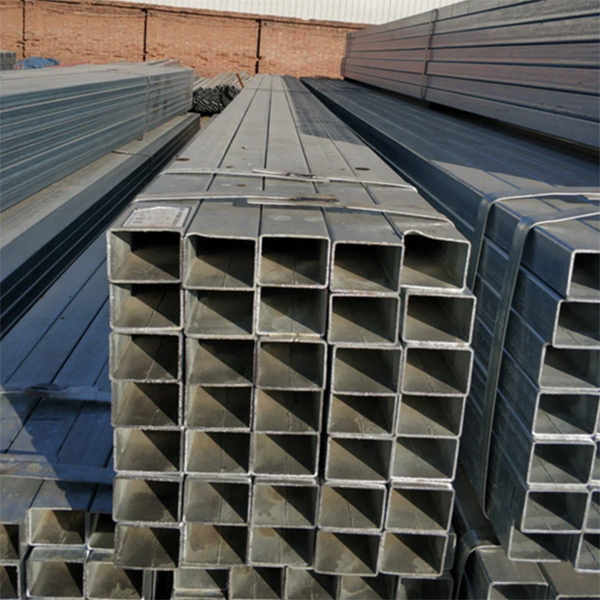

Square Structural Steel Tubing

Square structural steel tubing, tseem hu ua welded yeeb nkab, yog ua los ntawm steel phaj los yog sawb tom qab crimping txoj kev welded square yeeb nkab.

Square structural steel tubing, Cov khoom siv feem ntau yog: Q235A, Q235C, Q235B, 16Mn, 20#, Q345, L245, L290, X42, X46, X60, X80, 0Cr13, 1Cr17, 00Nb19N19, thiab

Welded stainless hlau yeeb nkab rau kho kom zoo nkauj (GB / T 18705-2002), welded stainless hlau yeeb nkab rau tsev kho kom zoo nkauj (JG / T 3030-1995), welded steel yeeb nkab rau cov dej tsis tshua muaj siab thauj mus los (GB / T 3091-2001), thiab welded steel yeeb nkab rau tshav kub exchanger (YB4103-2000).

Txheej txheem ntau lawm

Square structural steel tubing, nqaim blanks yuav siv tau los tsim welded kav nrog loj diameters, thiab blanks ntawm tib lub dav siv tau los tsim welded kav nrog txawv diameters.Tab sis piv nrog tib qhov ntev ntawm txoj kab ncaj nraim square yeeb nkab, qhov ntev vuam nce los ntawm 30 ~ 100%, thiab qhov ceev ntau lawm yog qis dua.

Loj los yog tuab nyob rau hauv txoj kab uas hla square structural steel tubing, Feem ntau ua los ntawm steel billet ncaj qha, thiab me me welded yeeb nkab nyias phab ntsa welded yeeb nkab tsuas yog yuav tsum tau ncaj qha welded los ntawm steel siv.Tom qab ib qho yooj yim polishing, cov hlau yog npaj txhij.Yog li ntawd, me me txoj kab uas hla welded yeeb nkab feem ntau siv ncaj seam vuam, txoj kab uas hla loj welded yeeb nkab feem ntau siv kauv vuam.

Shape Lub Performance

square structural steel tubing, Nws yog lub npe rau cov yeeb nkab square, uas yog cov yeeb nkab nrog qhov ntev ntawm ob sab.Nws yog ua los ntawm sawb hlau los ntawm cov txheej txheem daws thiab dov.Nquag, lub strip yog unpacked, tiaj tus, crimped, welded rau hauv ib puag ncig raj, thiab ces dov los ntawm lub round raj Q215 welded square raj thiab ces txiav mus rau hauv qhov ntev ntawm kev thov.Tus naj npawb ib txwm yog 50 rau ib pob.Lub zog hais txog kev ua haujlwm ntawm kev tiv thaiv kev puas tsuaj (zoo li yas deformation lossis tawg) ntawm Q215 welded square yeeb nkab cov ntaub ntawv nyob rau hauv static load.Vim hais tias cov load ntawm daim ntawv tensile, contraction, winding, shear thiab lwm txoj kev, vim hais tias lub zog kuj muab faib ua tensile zog, compressive zog, dabtsi yog khoov zog, shear zog thiab thiaj li nyob.Txhua yam ntawm lub zog feem ntau muaj kev sib cuag, ib txwm siv lub zog tensile raws li qhov tseem ceeb tshaj plaws lub zog rab koob.Lub zog los tiv thaiv kev puas tsuaj yog hu ua charge toughness.

Lub load rau ntawm qhov chaw uas muaj kev vam meej yog hu ua charge array load.Lub zog, plasticity thiab lub kaum sab xis sib tham tom qab lub square yeeb nkab nqi array toughness nyob rau hauv qhov kev txiav txim ntawm hlau nqi array load yog tag nrho cov tshuab muaj nuj nqi gauges nyob rau hauv qhov kev txiav txim ntawm static load ntawm Q215 welded square yeeb nkab.Hauv kev xyaum, ntau lub tshuab ua haujlwm rov qab ua haujlwm, nyob rau hauv ib puag ncig no tag nrho lub sijhawm rau qaug zog.Fatigue Angle yog ntsuas cov ntaub ntawv hlau mos thiab qib nyuaj ntawm rab koob.Txoj kev tsawg tshaj plaws ntawm lub kaum sab xis kho nyob rau hauv lub neej tam sim no yog lub siab lub kaum sab xis txoj kev, uas yog siv ib tug xov tooj ntawm cov zoo li cas ntawm lub taub hau siab nyob rau hauv ib tug tej yam load yog nias rau hauv lub xeem Q215 welded square tube cov ntaub ntawv nto, raws li mus rau lub siab mus rau theem los txiav txim lub kaum sab xis tus nqi.Ob peb txoj kev siv yog HB, HRA, HRB, HRC thiab HV.Angular plasticity yog hais txog lub zog ntawm cov ntaub ntawv hlau nyob rau hauv load, yas deformation (mus tas li deformation) yam tsis muaj kev puas tsuaj.Yas Q215 welded square raj uas tsis yog-tus qauv seamless square raj yog seamless round raj extrusion molding.Lub seamless raj thiab weld cov ntsiab lus txhais tau tias, nws yog lub taub hau square raj hom (torque raj), tus ntsuj plig ntawm ntau yam khoom muaj peev xwm los ua ib tog yeeb nkab (square torque tube), nws yog nruab nrab ntawm, vim li cas, siv dab tsi yog lub hauv paus, cov haiv neeg tsawg Q215 welded square tube steel tube raws li cov haiv neeg tsawg, rau square tube qauv, whitewash square raj, architects yeeb nkab (square torque tube), thiab lwm yam Square raj Taw qhia Square raj ua haujlwm.

Tshuaj muaj pes tsawg leeg

S460N khoom

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | CEV |

| max 0.2 hli | max 0.6 hli | 1-1.7 Nws | max 0.8 hli | max 0.03 Nws | max 0.025 | max 0.3 hli | max 0.1 hli | max 0.2 hli | max 0.025 | max 0.05 Nws | max 0.05 Nws | max 0.02 Nws | max 0.55 Nws | max 0.55 Nws |

S420N khoom

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | CEV |

| max 0.2 hli | max 0.6 hli | 1-1.7 Nws | max 0.8 hli | max 0.03 Nws | max 0.025 | max 0.3 hli | max 0.1 hli | max 0.2 hli | max 0.025 | max 0.05 Nws | max 0.05 Nws | max 0.02 Nws | max 0.55 Nws | max 0.52 |

S420NL khoom siv:

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | CEV |

| max 0.2 hli | max 0.6 hli | 1-1.7 Nws | max 0.8 hli | max 0.025 | max 0.02 Nws | max 0.3 hli | max 0.1 hli | max 0.2 hli | max 0.025 | max 0.05 Nws | max 0.05 Nws | max 0.02 Nws | max 0.55 Nws | max 0.52 |

S460NL khoom:

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | CEV |

| max 0.2 hli | max 0.6 hli | 1-1.7 Nws | max 0.8 hli | max 0.025 | max 0.02 Nws | max 0.3 hli | max 0.1 hli | max 0.2 hli | max 0.025 | max 0.05 Nws | max 0.05 Nws | max 0.02 Nws | max 0.55 Nws | max 0.55 Nws |

Mechanical Properties

S460N khoom

| Nominal thickness (hli): | rau 100 | 100-200 |

| Rm- Tensile zog (MPa) | 540-720 : kuv | 530-710 : kuv |

| Nominal thickness (hli): | rau 16 | 16-40 : kuv | 40-63 : kuv | 63-80 ib | 80-100 | 100-150 | 150-200 |

| ReH- Tsawg tshaj tawm lub zog (MPa) | 460 | 440 | 430 | 410 | 400 | 380 | 370 |

| KV- Impact zog (J) longitud., (+N) | + 20 ° 55 | 0 ° 47 | -10 ° 43 | -20 ° 40 | |

| KV- Impact zog (J) transverse, (+ N) | + 20 ° 31 | 0 ° 27 | -10 ° 24 | -20 ° 20 | |

| Nominal thickness (hli): | rau 16 | 16-40 : kuv | 40-63 : kuv | 63-80 ib | 80-200 |

| A- Min.elongation Lo = 5,65 √ Yog li (%) | 17 | 17 | 17 | 17 | 17 |

S420N khoom siv:

| Nominal thickness (hli): | rau 100 | 100-200 | 200-250 |

| Rm- Tensile zog (MPa) | 520-680 : kuv | 500-650 | 500-650 |

| Nominal thickness (hli): | rau 16 | 16-40 : kuv | 40-63 : kuv | 63-80 ib | 80-100 | 100-150 | 150-200 | 200-250 |

| ReH- Tsawg tshaj tawm lub zog (MPa) | 420 | 400 | 390 | 370 | 360 | 340 | 330 | 320 |

| KV- Impact zog (J) longitud., (+N) | + 20 ° 55 | 0 ° 47 | -10 ° 43 | -20 ° 40 | |

| KV- Impact zog (J) transverse, (+ N) | + 20 ° 31 | 0 ° 27 | -10 ° 24 | -20 ° 20 | |

| Nominal thickness (hli): | rau 16 | 16-40 : kuv | 40-63 : kuv | 63-80 ib | 80-200 | 200-250 |

| A- Min.elongation Lo = 5,65 √ Yog li (%) | 19 | 19 | 19 | 18 | 18 | 18 |

S420NL khoom siv:

| Nominal thickness (hli): | rau 100 | 100-200 | 200-250 |

| Rm- Tensile zog (MPa) | 520-680 : kuv | 500-650 | 500-650 |

| Nominal thickness (hli): | rau 16 | 16-40 : kuv | 40-63 : kuv | 63-80 ib | 80-100 | 100-150 | 150-200 | 200-250 |

| ReH- Tsawg tshaj tawm lub zog (MPa) | 420 | 400 | 390 | 370 | 360 | 340 | 330 | 320 |

| KV- Impact zog (J) longitud., (+N) | + 20 ° 63 | 0 ° 55 | -10 ° 51 | -20 ° 47 | -30 ° 40 | -40 ° 31 | -50 ° 27 | |

| KV- Impact zog (J) transverse, (+ N) | + 20 ° 40 | 0 ° 34 | -10 ° 30 | -20 ° 27 | -30 ° 23 | -40 ° 20 | -50 ° 16 | |

| Nominal thickness (hli): | rau 16 | 16-40 : kuv | 40-63 : kuv | 63-80 ib | 80-200 | 200-250 |

| A- Min.elongation Lo = 5,65 √ Yog li (%) | 19 | 19 | 19 | 18 | 18 | 18 |

S460NL khoom:

| Nominal thickness (hli): | rau 100 | 100-200 |

| Rm- Tensile zog (MPa) | 540-720 : kuv | 530-710 : kuv |

| Nominal thickness (hli): | rau 16 | 16-40 : kuv | 40-63 : kuv | 63-80 ib | 80-100 | 100-150 | 150-200 |

| ReH- Tsawg tshaj tawm lub zog (MPa) | 460 | 440 | 430 | 410 | 400 | 380 | 370 |

| KV- Impact zog (J) longitud., (+N) | + 20 ° 63 | 0 ° 55 | -10 ° 51 | -20 ° 47 | -30 ° 40 | -40 ° 31 | -50 ° 27 | |

| KV- Impact zog (J) transverse, (+ N) | + 20 ° 40 | 0 ° 34 | -10 ° 30 | -20 ° 27 | -30 ° 23 | -40 ° 20 | -50 ° 16 | |

| Nominal thickness (hli): | rau 16 | 16-40 : kuv | 40-63 : kuv | 63-80 ib | 80-200 |

| A- Min.elongation Lo = 5,65 √ Yog li (%) | 17 | 17 | 17 | 17 | 17 |

Khoom Qhia