TC2 Titanium Alloy Aheet Phaj

TC2 Titanium Alloy Aheet Phaj, Ib qho hlau raws li titanium nrog lwm cov khoom ntxiv.Muaj ob hom homogenous crystals nyob rau hauv titanium: α titanium nrog tuab hexagonal qauv yog qis dua 882 ℃, thiab β titanium nrog lub cev nruab nrab lub voos xwmfab yog siab dua 882 ℃.

Technical xav tau:

1. Cov tshuaj muaj pes tsawg leeg ntawm titanium thiab titanium alloy phaj yuav tsum ua raws li cov kev cai ntawm GB / T 3620.

2. Nyob rau hauv rooj plaub ntawm kev tshuaj xyuas, qhov tso cai sib txawv ntawm cov tshuaj muaj pes tsawg leeg yuav tsum ua raws li cov kev cai ntawm GB / T 3620.

ib.qhov tso cai sib txawv ntawm lub thickness ntawm lub phaj yuav tsum ua raws li cov kev cai ntawm Table 1.

b.qhov tso cai sib txawv ntawm phaj dav thiab ntev yuav tsum ua raws li cov lus qhia 2.

c.cov ces kaum ntawm lub phaj yuav tsum tau txiav rau hauv cov ces kaum kom deb li deb tau.Qhov sib txawv yuav tsum tsis txhob tshaj qhov ntev thiab dav ntawm daim ntawv

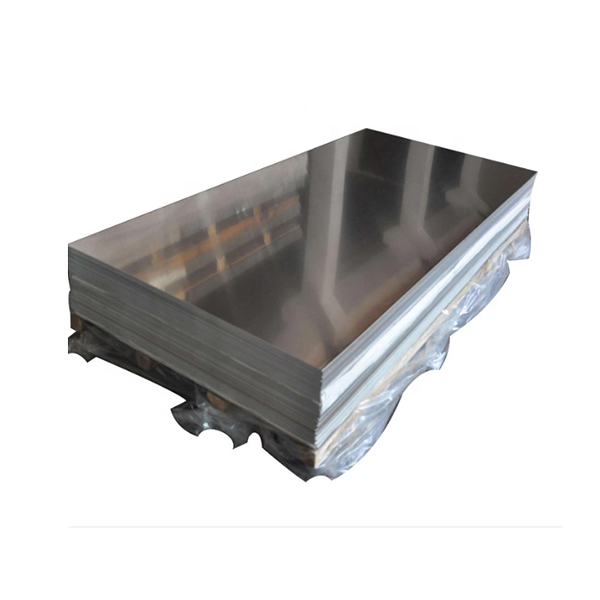

TC2 Titanium Alloy Aheet Phaj, Cov Khoom Specification

T 0.5-1.0mm × W1000mm × L 2000-3500mm

T 1.0-5.0mm × W1000-1500mm × L 2000-3500mm

T 5.0-30mm × W1000-2500mm × L 3000-6000mm

T 30-80mm × W1000mm × L 2000mm

TC2 Titanium Alloy Aheet Phaj, Ntau Lawm

Lub xeev ua haujlwm kub (R) Lub xeev ua haujlwm txias (Y) Lub xeev Annealing (M)

TC2 Titanium Alloy Aheet Phaj, Siv Tus Qauv

1: GB 228 Hlau tensile xeem txoj kev

2: GB / T 3620.1 Titanium thiab titanium alloy qib thiab tshuaj muaj pes tsawg leeg

3: GB / T3620.2 Titanium thiab titanium alloy ua cov khoom siv tshuaj lom neeg thiab muaj pes tsawg leeg tso cai sib txawv

4: GB 4698 Hiav txwv nto txoj kev rau tshuaj ntsuam xyuas ntawm titanium, titanium thiab ferroalloys

TC2 Titanium Alloy Aheet Phaj, Cov Kev Xav Tau

1: Cov tshuaj muaj pes tsawg leeg ntawm titanium thiab titanium alloy phaj yuav tsum ua raws li cov kev cai ntawm GB / T 3620.1.Nyob rau hauv rooj plaub ntawm kev tshuaj ntsuam xyuas, qhov tso cai sib txawv ntawm cov tshuaj muaj pes tsawg leeg yuav tsum ua raws li cov kev cai ntawm GB / T 3620.2.

2: Qhov tso cai sib txawv ntawm lub thickness ntawm lub phaj yuav tsum ua raws li cov kev cai ntawm Table 1.

3: Qhov tso cai sib txawv ntawm phaj dav thiab ntev yuav tsum ua raws li cov lus qhia 2.

4: Cov ces kaum ntawm lub phaj yuav tsum tau txiav rau hauv cov ces kaum kom deb li deb tau.Qhov sib txawv yuav tsum tsis txhob tshaj qhov ntev thiab dav ntawm daim ntawv

Alloying

TC2 Titanium Alloy Aheet Phaj, Ib qho hlau raws li titanium nrog lwm cov khoom ntxiv.Muaj ob hom homogenous crystals nyob rau hauv titanium: α titanium nrog tuab hexagonal qauv yog qis dua 882 ℃, thiab β titanium nrog lub cev nruab nrab lub voos xwmfab yog siab dua 882 ℃.

(1) Alloying cov ntsiab lus tuaj yeem muab faib ua peb pawg raws li lawv cov txiaj ntsig ntawm theem hloov pauv kub:

α -stable ntsiab, xws li txhuas, carbon, oxygen thiab nitrogen, stabilize α theem thiab nce theem hloov kub.Aluminium yog lub ntsiab alloying ntawm titanium alloy, uas muaj cov txiaj ntsig zoo ntawm kev txhim kho lub zog ntawm cov hlau ntawm chav tsev kub thiab kub, txo qhov tshwj xeeb lub ntiajteb txawj nqus thiab ua kom cov elastic modulus.

(2) β -stable ntsiab yuav muab faib ua ob hom: isocrystalline thiab eutectoid.Cov khoom ua los ntawm titanium alloy

Cov qub muaj molybdenum, niobium, vanadium thiab lwm yam;Cov tom kawg muaj chromium, manganese, tooj liab, hlau, silicon thiab lwm yam.

(3) Cov ntsiab lus uas tsis tshua muaj txiaj ntsig rau theem hloov pauv kub yog qhov nruab nrab, xws li zirconium thiab tin.

Oxygen, nitrogen, carbon thiab hydrogen yog lub ntsiab impurities hauv titanium alloys.Lub solubility ntawm oxygen thiab nitrogen nyob rau hauv α theem yog ntau dua, uas muaj ib tug tseem ceeb ntxiv dag zog rau lub titanium alloy, tab sis txo lub plasticity.Cov ntsiab lus ntawm oxygen thiab nitrogen hauv titanium feem ntau yog qis dua 0.15 ~ 0.2% thiab 0.04 ~ 0.05%, feem.Hydrogen muaj me ntsis solubility nyob rau hauv α theem, thiab ntau heev hydrogen yaj nyob rau hauv titanium alloys ua hydrides, uas ua rau cov alloy nkig.Hydrogen cov ntsiab lus hauv titanium alloy feem ntau yog tswj hauv qab 0.015%.Lub dissolution ntawm hydrogen nyob rau hauv titanium yog reversible thiab yuav raug tshem tawm los ntawm lub tshuab nqus tsev annealing.

Tshuaj muaj pes tsawg leeg

| Qib | N | C | H | Fe | O | Al | V | Pa | Mo | Ni | Ti |

| Gr1 | 0.03 ib | 0.08 ib | 0.015 ib | 0.2 | 0.18 | / | / | / | / | / | Bal |

| Gr 2 | 0.03 ib | 0.08 ib | 0.015 ib | 0.3 | 0.25 | / | / | / | / | / | Bal |

| Gr 3 | 0.05 Nws | 0.08 ib | 0.015 ib | 0.3 | 0.35 Nws | / | / | / | / | / | Bal |

| Gr4 | 0.05 Nws | 0.08 ib | 0.015 ib | 0.5 | 0.4 | / | / | / | / | / | Bal |

| Gr 5 | 0.05 Nws | 0.08 ib | 0.015 ib | 0.4 | 0.2 | 5.5-6.75 Nws | 3.5-4.5 | / | / | / | Bal |

| gr 7 | 0.03 ib | 0.08 ib | 0.015 ib | 0.3 | 0.25 | / | / | 0.12-0.25 dr hab | / | / | Bal |

| gr9 ua | 0.03 ib | 0.08 ib | 0.015 ib | 0.25 | 0.15 | 2.5-3.5 | 2.0-3.0 Nws | / | / | / | Bal |

| Gr 12 | 0.03 ib | 0.08 ib | 0.015 ib | 0.3 | 0.25 | / | / | / | 0.2-0.4 hli | 0.6-0.9 hli | Bal |

Tensile zog

| Qib | Elongation (%) | Tensile zog (Min) | Yield zog (Min) | ||

| ksi ua | Mpa | ksi ua | Mpa | ||

| Gr1 | 24 | 35 | 240 | 20 | 138 |

| Gr 2 | 20 | 50 | 345 | 40 | 275 |

| Gr 3 | 18 | 65 | 450 | 55 | 380 |

| Gr4 | 15 | 80 | 550 | 70 | 483 ib |

| Gr 5 | 10 | 130 | 895 ib | 120 | 828 ib |

| gr 7 | 20 | 50 | 345 | 40 | 275 |

| gr9 ua | 15 | 90 | 620 | 70 | 438 ib |

| Gr 12 | 18 | 70 | 438 ib | 50 | 345 |

Titanium thiab Alloy khoom

| Khoom npe | Specifications |

| Titanium pas nrig & Bar & Ingots | Ф3mm ~ Ф1020mm, qhov siab tshaj plaws yog mus txog 12t |

| Titanium Slab | (80 ~ 400) hli × (~ 1500) hli × (~ 2600) hli |

| Titanium Forgings | Nyhav ib thooj ≤2000kg |

| Titanium kub dov daim hlau | (4 ~ 100) hli × (800 ~ 2600) hli × (2000 ~ 12000) hli |

| Titanium Cold-dov Sheet | (0.01 ~ 4.0) hli × (800 ~ 1560) hli × (~ 6000) hli |

| Titanium Ntawv Nyiaj / Strips | (0.01 ~ 2.0) hli × (800 ~ 1560) hli × L |

| Titanium Tubes / Cov kav dej | Ф (3 ~ 114) hli × (0.2 ~ 5) hli × (~ 15000) hli |

| Cov qauv | GB, GJB, ASTM, AMS, BS, DIN, DMS, JIS, ГОСт |

| Qib Titanium |

|

Khoom Qhia